Sharp distance sensors.

Just some notes and hints on how to use them with your NXT, with a minimum of additional hardware.

This is not complete yet...

The last part math/calibration, is still missing.

I discovered a new color ;)

If you still stick to your original Lego sensor equipment, you probably already did get far, but never back...

The well known and popular optical distance sensors from Sharp

(see here

for a complete reference and datasheets; Note 10/2009: Sharp removed

the sensors from their pages. Could be a bad sign...) are a "superior replacement" (aka.: a starter drug to the amazingly comprehensive

and complex field of object detection) for your nice looking ultrasonic rangefinder (sometimes, it really finds one ;)

To name a few:

- GP2D120 (old), 4-30cm

- GP2D12 (old), 10-80cm

- GP2Y0A02, 20-150cm

- GP2Y0A700 (GP2Y0A710K0F), up to 500cm

- ...

If you are not familiar with these sensors, read (at least) the datasheet first. Otherwise some aspects of the following might not be obvious...

The direct NXT usage of the analog output type Sharp sensors faces you with three "problems":

- output impedance

- pulsed current consumption/power supply

- non linear distance/voltage dependence

Basic Operation and Pitfalls

The Sharp sensors measure the distance by triangulation. The position of an emitted spot of IR-light is detected by an 1D-array of photosensitive elements and converted into an analog output voltage.

Although the term "analog", as a specification of the output type of the Sharp sensors, makes us believe they put out

an arbitrary range of values (voltage), this is not true.

The output voltage has discrete steps:

distance set to a range between two steps

For all analyses, measurements or calibrations you perform, always make sure the distance is set to a range where it does not cause steps like shown in the screenshot above.

Keep this is mind while programming your equipment, which for sure requires some filtering...

Output Impedance

Interfacing a Sharp distance sensor directly to your NXT input port pin 1 (A/D) converter will not work. You will get nothing else but 0x3FF values from the NXTs A/D converter.If you unintendedly plug your new circuit into a port which has 9V turned on, it might blow up. Considering wrong handling is always a good choice.

But, wait! Just building a 9V-proof impedance converter is not enough...

Power Supply and Current Spikes

The Sharp distance sensors' voltage supply is specified from 4.5-5.5V, a typical Lego-NXT puts out a voltage of ~4.8V. Nice! Obviously one can directly attach it...

Well, not quite...

This is what our (or at least mine) NXT power supply looks like:

NXT power supply output (port pin 4) @50mA resistive load; Click to enlarge...

(AC coupled measurement distorts the real signal offsets a little)

Now you probably understand, one of the hundred possible reasons, why some people are having problems with jittering A/D measurements

after they hooked up their own equipment ;)

It is getting even more worse if motors are activated or resistive losses (cable, NXTs internal current limiter, ...) sum up

under pulse conditions.

But wait again!

Due to its internal sampling operation and "long-term" (it's all relative ;-) averaging, the Sharp sensor has an impressive

power supply rejection ratio. At least if you consider its internal photo-amplifiers are fed with a few nA...

Although a clean voltage supply is always a good thing, the major reason for unstable measurements are caused by

the pulsed current consumption of the Sharp sensor itself.

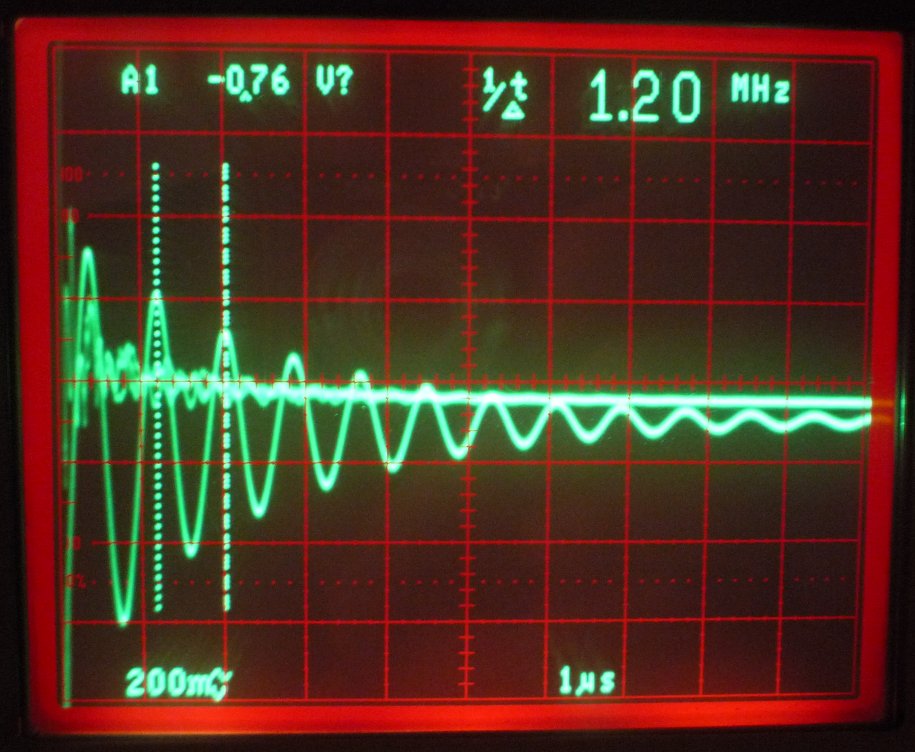

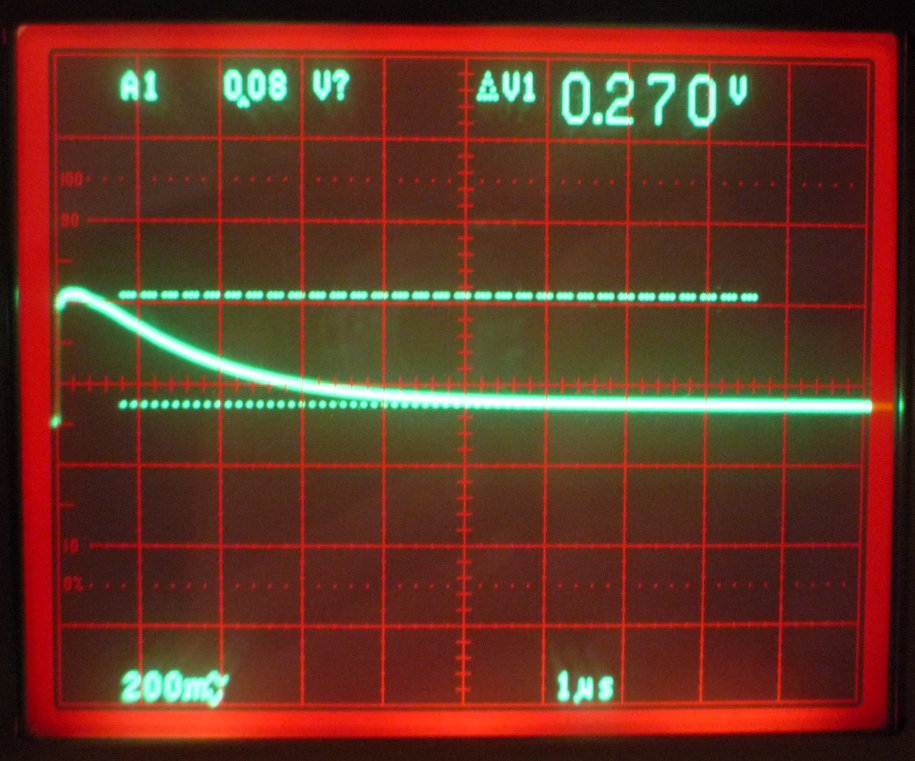

This is what it looks like...

AC coupling; 230mV => 23mA

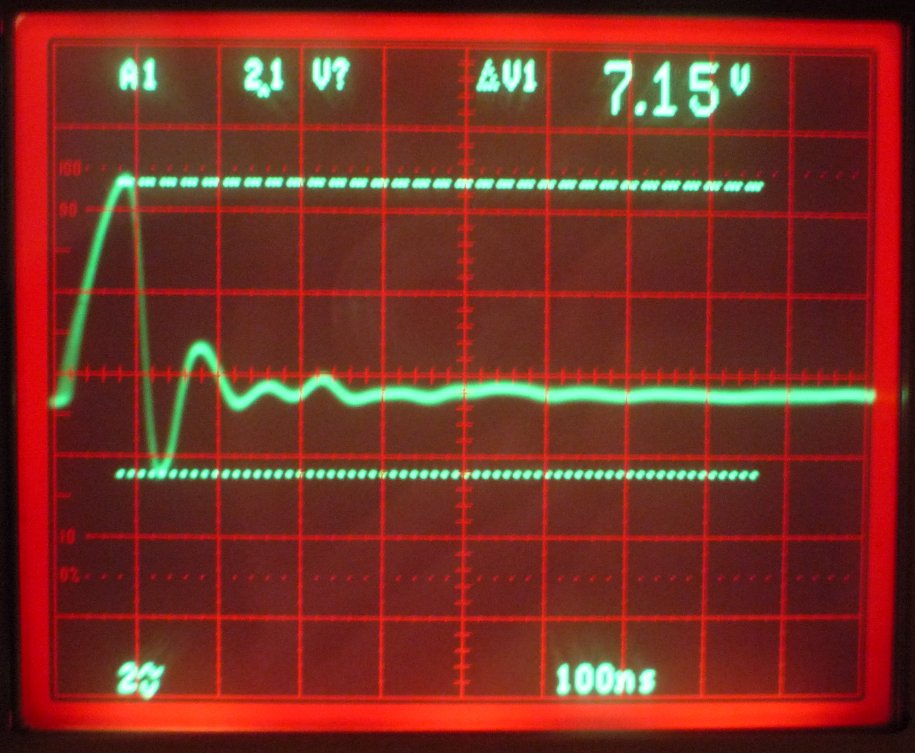

I am going to skip transmission line theory here, but if you have no clue about what it means to fire a "short" pulse through a real, unterminated cable, this it what it looks like...

The lesser the resistance (and capacitance) of the cable, the more you will be remembered of its inductance (it

lacks some "damping components"). Real cables can form really good resonant circuits...

This is one of the many reasons why your CATx network cables, telephone lines, ... are all of a twisted pair type, which

have a defined characteristic impedance and a termination.

Even though a very "short" time, the voltage at the end of the cable reaches ~10V (remember, this is an AC shot; the decaying wave already has 5V), and drops down to ~3V.

Some slower views of the supply voltage of the sensor, directly powered by a NXT...

All views AC coupled.

|

|

|

And the resulting signal output of the sensor:

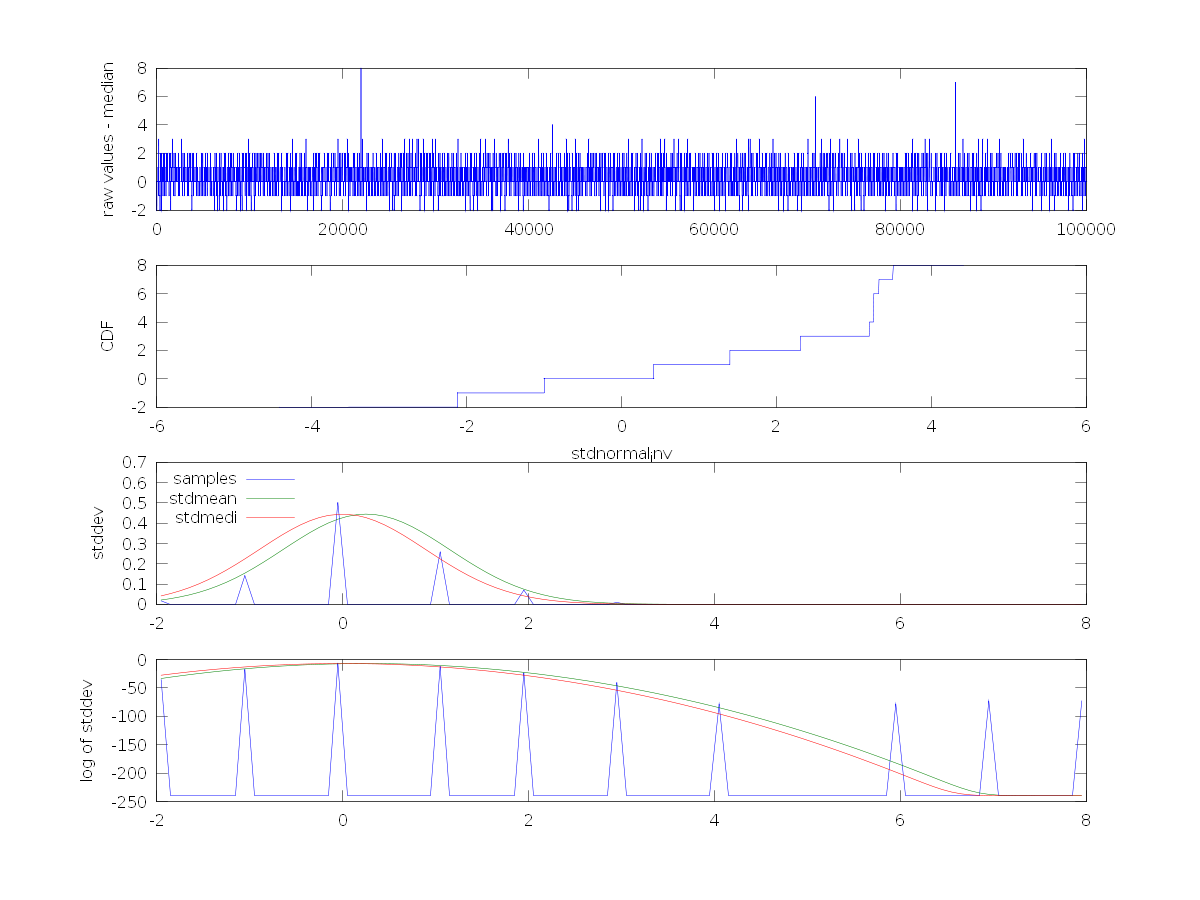

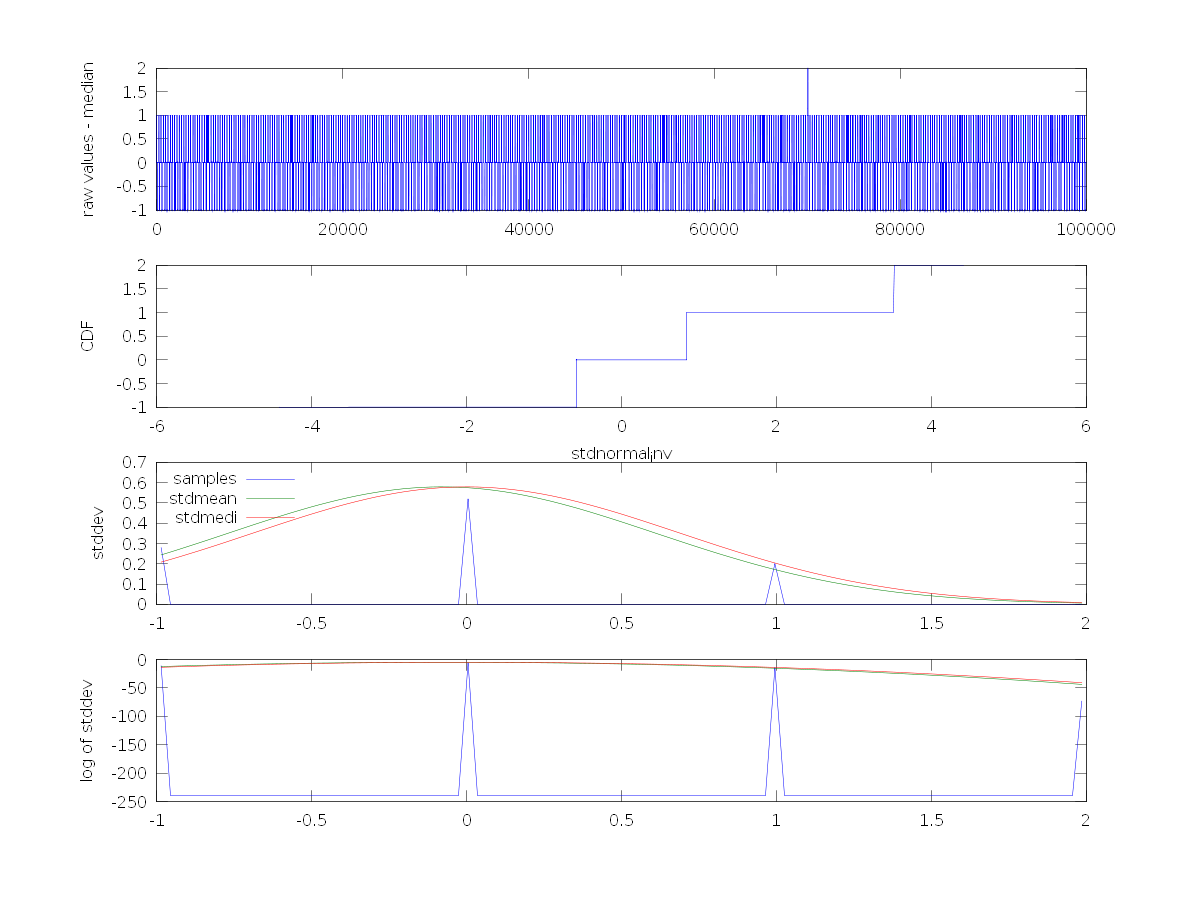

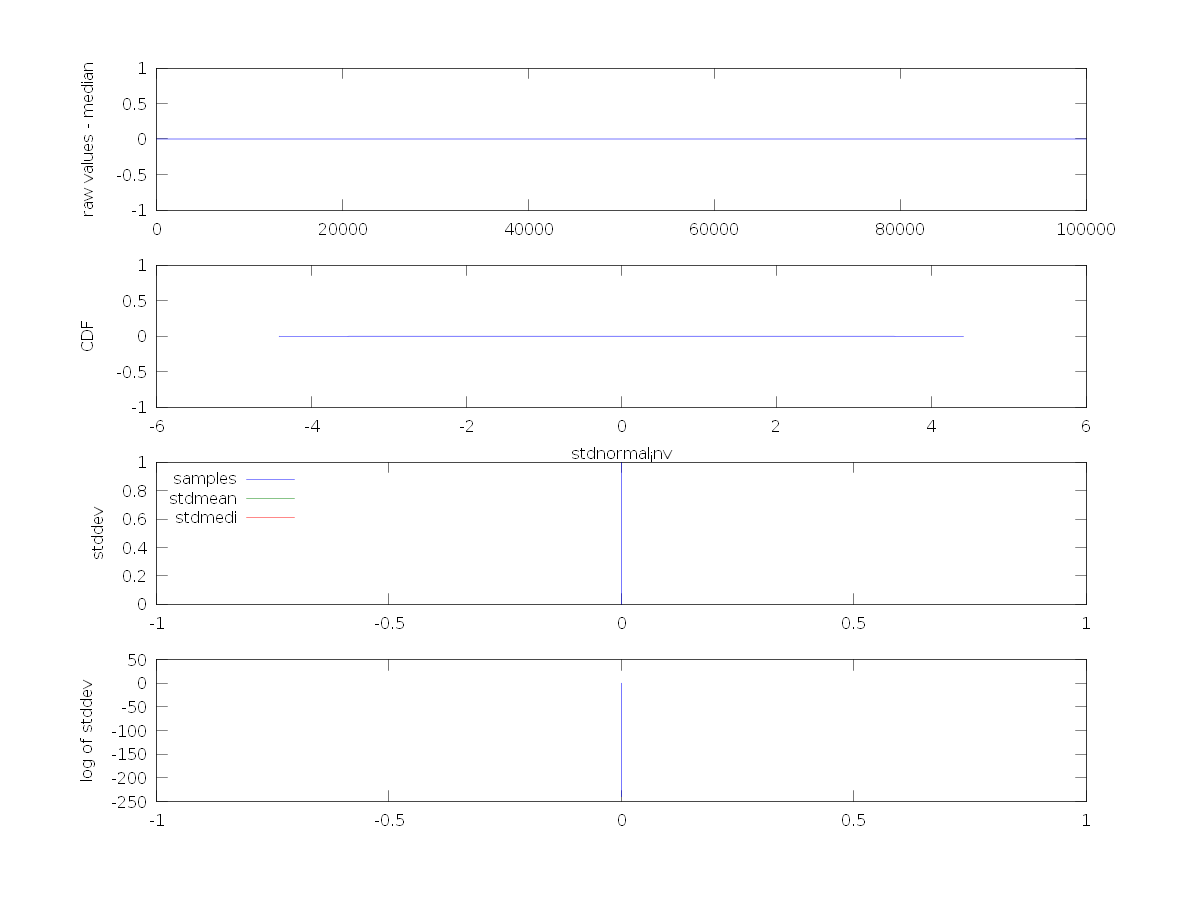

I performed a tiny and stupid analysis of 100'000 measured values, taken directly by the NXT

(pbLua program and script for

GNU Octave).

Yes, there are indeed far better (and statistically correct ;-) possibilities for an analysis (and better image

resolutions too, I must admit), but I wanted to keep this as simple as possible...

From top to bottom:

- raw values with removed offsets (value(n)-median(all_data))

- CDF, assuming a normal distribution

- PDF (not what you think ;)

- PDF with logarithmic weight and 1e-12 offset: 20*log10(value+1e-12), to make the spikes visible

The values jitter +-3 digits with some outrageous peaks up to <20 digits and down to >7 and an autocorrelation clearly reveals a time dependency:

| sensor directly attached, no filtering/blocking | autocorrelation of the first 5000 values |

|

|

The easiest way to find out which of these effects are cause by the noisy, spiky power supply of the NXT is to operate the sensor with a battery pack. I used a 4xNiMH @5.1V pack, buffered with a medium ESR 330u capacitor. Cable length from buffer to sensor was ~10cm (AWG 26).

No noteworthy changes...

| sensor directly attached, no filtering/blocking | autocorrelation of the first 5000 values | fft (notice that x axis' unit is ms) |

|

|

|

All the characteristic patterns in the autocorrelation result from two different, overlaying time constants:

First of all the Sharp sensor, with fixed pulse packets repeated at about ~40ms and then, the sampling rate (~250us, *1*) of the

NXTs A/D converter. Because both times are somewhat fixed, every n-th measurement of the A/D converter will meet

the same point (e.g. a rising edge) after the same time, hence causing the same error.

The result of an FFT clearly reveals the repetition rate of the sensor: ~40ms.

(*1*) measured with a stop watch during acquisition of 100000 data points (~25s).

A look at the corresponding output signals of the sensor.

Top row: NXT powered

Bottom row: Battery powered

|

|

|

|

|

|

Now why do these cause problems?

Beside the many other things that may happen, a few are:

-

A static (or slow) fluctuation of any power supply.

Any change to the voltage/current supply may affect the output of an electronic component (PSRR: power supply rejection ratio, you may have heard about that; A common spec., for, e.g., OPs etc...). This possibly makes your LED "brighter" or "darker", internal references may fluctuate, a component may get out of balance and create offset shifts, and, and, and... -

Fast transients.

These will shoot through any internal capacitance, including the parasitic and intrinsic ones. This may turn on transistors or FETs (Miller capacitance; Ucb, Udg), go right across the sample and hold stage of any A/D converter, and, and, and... -

Demodulated RF.

Every non-linear component (e.g. diode) may demodulate RF signals and bring up ugly, "energy-rich" (relative) low frequency components, create offset shifts, and, and, and...

A single diode (which in fact is present in every semiconductor) might cause a multiplicity of problems:

- DC offsets

- low frequency components

- slow transients

- ...

...

This time, most of the problems are caused by the sensors itself. Its fast switching transients on the power supply shoot through, up to the output and hence right into a, not very well filtered, A/D input pin.

At least for power supplies there's a simple way avoiding these:

A low pass filter (or even more simply: a capacitor, damping the "RF").

As an example: What will a 10nF capacitor (high-frequency capable, of course) do at 10MHz.

It has an impedance of:

Xc=1/(2*pi*f*C) = 0.16E

If you attach a (pure resistive) cable of the same (resistive) impedance, you just halved the amplitude of the RF signal at 10MHz (-6dB) and it will decrease by another 20dB per decade (1/10). A very effective mechanism of getting rid of unwanted spectral components. If the RF fades, any possibly demodulated signal will decrease by the same factor.So, for really "high" frequency components adding a "small" capacitor (remember, this is all relative ;) is sufficient. But adding a small capacitance here, will not help. The resulting "RF" is the effect, but not the cause...

We still have switching transients and resistive losses and a fast voltage drop caused by an pretty fast current pulse flowing across the cable...

Hindering the current pulse from flowing through the cable or at least, slowing it down and damping its effects on the transmission line is a second thing we can do. We need a kind of an energy tank for this... Yes, an even larger capacitor ;)

To estimate (aka.: coarse guess ;) its size we simply assume that we would like to limit the voltage drop below 100mV during a constant current flow of 30mA within 130us (a Sharp sensors pulse length).

capacitance=voltage*charge; charge=current*time

C*U=Q <=> C*U=I*t <=> C=(I*t)/U

C=(30mA*130us)/100mV <=> C = 45uF

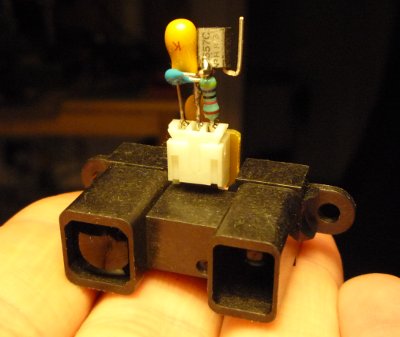

Soldering in a 10u tantalum capacitor (left picture) across the inputs of the sensor, already changes a lot...

On the right side, a ceramic 47u was added.

Note: There's another component visible, an OPA336 operational amplifier. This will be explained later...

|

|

At least for a short time, the capacitor can deliver the demanded current.

All the ringing is gone...

(including the resistance of the unbuffered 4xNiMH pack, of course!)

Attached to a NXT, which additionally offers a 220u capacitor, right at the port...

sensor voltage, 10u tantalum

|

sensor voltage, 10u tantalum + 100u (std.)

|

Does this improve the jittering measurements?

A little better than before...

Less than a handful spikes and a lower deviation.

Signal Filter

The input voltage quality can not (easily) be improved. But until now, we did not take care of the output signal itself. The Sharp sensors update their output every ~40ms (GP2D12; others may vary), right after one 32-pulse-train is over:

Take this into account while programming your software!

While the output (or the sensor) is that slow, further low-pass filtering of the signal won't hurt. An usual (aka.: "my") approach is to use 1/10 of the pulse width, I therefore applied an low pass filter with a corner-frequency of ~38Hz (or in the time domain, as time constant: ~4.7ms).

(Note: Actually the filter forms a little more than a simple low-pass, because it has different time constants

for positive and negative edges. Additionally the filter was split into two parts:

One at the sensor, the other right at the input port).

To bring this to an end:

What about the measurements?

This is why I noted that there are better analyses.

Somehow, the CDF/PDF is ridiculous with a handful of discrete values ;)

secret tricks, #1

|

secret tricks, #2

|

To cut an, almost unbearable, long story short: Add a capacitor. But at least, _now_ you know why... 8-)

The filter stuff will be explained later on...

Powering Equipment from NXT

How much power can one derive from a NXT port, pin 4? How much sensors can I attach?

Short form: 100mA (3 sensors) if nothing else is attached (to input and motor ports).

Otherwise, one sensor, 30mA.

At 100mA, the NXT voltage will drop down to ~4.5V. Although this does not necessarily mean the sensors will

immediately stop operating, their values will become more and more imprecise. Additionally, they do not

operate synchronously, hence the influence (voltage drops, etc...) from one sensor to another will rise...

Long form:

This is the port current limiting circuit in the NXT:

I strongly recommend the usage of a battery pack (4-5xNiMH) and a simple (but powerful ;) linear 5.0V regulator.

Buffer the battery pack with (proposed) 47-100u per attached sensor, keep the leads short and solder a

tantalum or ceramic capacitor (10u-47u) right across the sensor power pins.

Avoid ground (or other cable) loops and do not use this modular cable stuff (the flat ones that came with your NXT...).

Use something shielded and twisted and separate your signal shielding from the power supply... (do not overdo; keep your

hands off MICC cables 8-). Almost any audio cable will be fine.

Connect the shielding at one end only if your NXT is used as the power-supply (left the other one open to avoid loops).

Depending on your robot (plastic, metal, wood, ...) you should as well take care of the sensor's mounting and position.

Although it looks like plastic, it indeed is conductive and can create unwanted ground loops (unlikely) or pickup other

"noise" (a conductive housing loses its shielding capabilities if it is directly exposed to a fluctuating potential).

On the other hand, a grounded sensor is less sensitive to radiated EM fields, for example a 20A brush-less motor ;)

Isolated or grounded. Choose wisely or use trial-and-error...

IR Shots

Just some pictures. GP2D12 in action...

a look at the IR LED

|

the light spot from a distance of 25cm

|

useless but interesting; sender...

|

and receiver; UFOs %)

|

Output Stage Analysis

Now, what's wrong with the output stage of the Sharp sensors?Basically nothing, except that the Sharp designer's implementation is not directly compatible to the NXT's input stage.

Obviously, simply characterising the output stage as "high impedance" is not the complete truth... In fact, we just discovered that the output is of a "push-type" (cf.: push-pull), which means it indeed is able to "source" current (output) but can not sink it (input).

But we still can assume more:

The rising, linear slope indicates a current source (or at least something that appears like one).

Calculating the differential current (delta U/delta R) for the part <80kOhms reveals the constant value:

Idiff = ~39uA

With nothing else but the values above, a little experience and knowledge, one now can create a simple model of the output stage. To verify this assumption and its accuracy, both, the measured as well as the calculated curve, a drawn one over another:

assumed model

|

characteristic curves

|

This should not get out of hand and end up in an electronics course. Just the facts:

Lowering the resistance to a little less than 100kOhms keeps the current-source fully-busy with sinking the current

flowing in from the external resistor:

Iin = Ur2/R2 = (U1-Ua)/R2 = (4.8V-1.0V)/100k = ~38uA

The current sink just can not sink any more, hence the emitter potential will rise and simply drop off the function of the transistor as a current amplifying element.As of then, the circuit only consists of the external resistor and the internal current source, producing this nice and straight characteristic curve above.

Below this resistance, assuming an ideal current source, the output voltage will be:

Ua = U1-Ur2 = 4.8V-Ur2 = 4.8V-(39uA * R2)

Ideal current sources, which would have an infinite internal resistance, do not exist. R4, with a calculated value of ~400kOhms, takes care of this and modifies the formula to:Ua = R4(U1-I1*R2)/(R2+R4) = 400k(4.8V-39uA*R2)/(R2+400k)

Circuits

There exist tons of appropriate circuits and possible solutions... Depending on your demands (filtering, safety, complexity, learning effect, ...) an unimaginable amount of combinations is possible.Here are some assorted proposals.

All circuits are presented with the following in mind:

| requirements/limitations | manufacturability |

|

|

In all cases, a calibration of the sensors is required, hence circuits may apply offsets or even have low non-linear transfer functions...

|

Almost There

A tuned, universal variant of the circuit above.

Choose a, not too fast (<1MHz), single supply, rail-to-rail OP. Changing the ratio of R3/R4 enables you set the amplification to whatever value. This circuit can be used for almost any equipment. Power supply from NXT might require additional filtering for the OP (see "Cutting Edge"). |

|

The Perfect Match

Why not bring multiple sensors, filtering, amplification AND calibration all together?

Read more about this, here. |

Math/Calibration

blabla...

ASkr 24/10/2009: more to come...

ASkr 11/2008 initial version

ASkr 09/2009 complete redesign

ASkr 10/2009 still in progress...