ParaMike - A printable, parabolic microphone for kids and geeks.

Features:

- printprintprintprintprintprint

- ...

Electronics for the ParaMike-Thing on Thingiverse.

ParaMike

|

a view inside

|

Hardware

This simple circuit does not require a PCB. A wire-wrapped version is much cheaper and can be built in less than an hour (assuming you already have all parts ;-), but keep an eye on the size!

The electronics consists of two parts, a PRE- and a POST-amplifier.

PRE amplifies the signal of the microphone, POST drives the headphones.

A kids or simple version can be built with PRE only (note component changes in the schematic), but

this does not support a volume control (unless YOU build it in).

PRE

The incoming signal from the electret microphone first hits C4, which removes RF components. R1, R2 and C1 form a filtered power supply path for the mic. Almost any electret mic capsule, with a diameter ~10mm, can be used. For some rare (usually the good and pricey ones) types, it might be necessary to decrease R1 and R2 until the static DC voltage at X2-1 matches to the microphone specs (typically >=1.5).

Because we'll only use a single voltage supply (a standard 9V battery is all we need) the signal

needs to be shifted to half the operating voltage before it is amplified: The LT1007, including R5, R6, C5 and C6 ("DC free", non-inverting amplifier) boosts the signal by ~40dB (V=~100), adds a second low pass (R6, C6) and a high pass filter (R5, C5). The result at pin 6 of the operational amplifier is a 100 times boosted signal including a 4.5V offset. The latter is removed ("blocked") by C3. Note the component value changes in the schematic if you only want to build the single PRE version. In this case, also skip the external potentiometer! An external, completely DC-free, potentiometer (10k, log) connects PRE and POST.

You might wonder about the "THIN FILM" attributes of R3, R4 and R6, but they really will

improve the signal to noise ratio

of the circuit. All other components noise contribution, except for the microphone itself, can be neglected: While reducing the resistor values for R3 and R4 (or R6) would improve the noise figure of the circuit, higher impedance microphones will not benefit from this:

If you manage to find an >2u2, 0805, X7R capacitor, you can do the same with R5, R6 and C6:

POST

There is not much to say about this driver stage...

Two parallelized halfs of a NJM4556,

a dual, high output power OP, will directly drive any headphone type. Including the filters of the POST stage, we now have a nice, human voice matched frequency response:

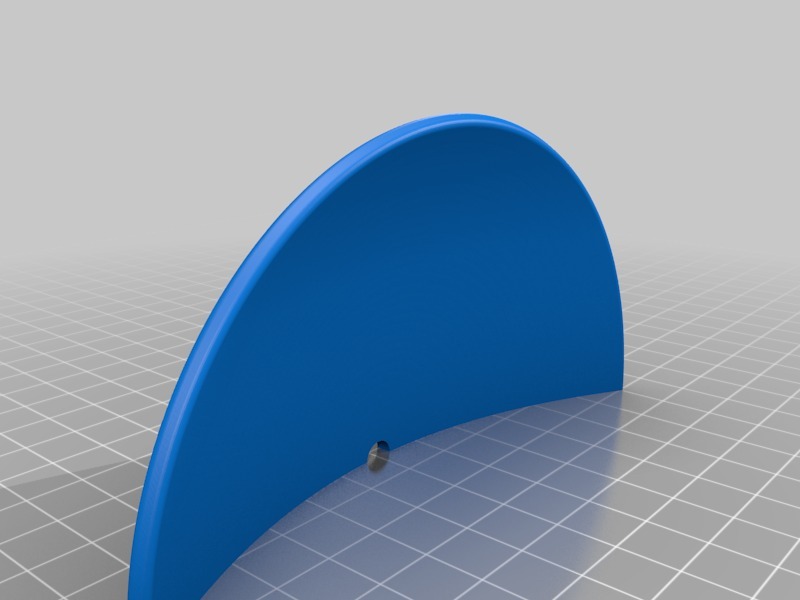

MechanicThe mechanic consists of five, printable parts:

Good news:

Glue both parts of the mirror together. If you enlarged the mirror, the diameter of the hole in the mirror increased too. If the hole got too large, use two washers.

Two options for the microphone:

No matter which option you choose, wrap a bit (or more if you enlarged the diameter of the

mirror) of cotton around the microphone. This helps damping impact sound. One side of the microphone holding bars has a cable conduit (cut-out) towards the inside. Thread the cable along this conduit, through the hole in the mirror and, last, the hole in the handle. If you did not enlarge the mirror, the cable consuit will only take a very thin (~1mm diameter) cable. Build all the electronics and stick it in. Beware of short circuits and wrap isulating tape around the PCBs. The rear of the handle has four holes. From top to bottom:

|

Some Useless Pics

Download

ParaMike:

Includes:

- schematic (PDF)

- layout (BRD)

- mechanic (STL)

- ...

DOWNLOAD: paramike-pre_hard_V11.zip Hardware PRE, V1.1

DOWNLOAD: paramike-post_hard_V11.zip Hardware POST, V1.1

DOWNLOAD: paramike_mech_V20.zip Mechanic (STL files), V2.0

ASkr 08/2012: initial public release