A simple, actually not even worth mentioning, USB to CMOS level EIA-232 (RS-232) converter.

Includes Parallax-Propeller-Reset (aka.: Propeller-Clip).

A typical example of wasting invaluable development time for completely other stuff...

Until now, I included the FTDI in every Propeller based board, I created. This time, I needed something more

"universal" (...) and detachable.

Two hours should have been enough. Something made it three days...

Lab's Law

DAY1:

- created schematic, incl. library, within 1 hour (incl. 1 coffee)

- created layout, within another hour (incl. 1 cold coffee)

- hit 'save'

- ***WHAM*** system off, lights out, a dog barks

- circuit breaker...

- found no fault but needed to detach all switching PSUs; 1 hour

- next, a coffee; machine: "system fault, call service"

- immediately disassembled the service friendly machine (triangular screw heads... idiots!); 2 hours

- found fault 1 hour later; a thermal sensor decided to leave the brewing unit, dangling around

- no problem, thermal adhesive is in the lumber-room

- middle row, undermost box of 6, all stacked on each other (thanks, DYMO!)

- 5 boxes on the floor, emptying themselves (do not trust paper, use tool-steel...)

- 4 hours pick-and-sort

- day gone...

- no coffee; tea, fine; floor, child, toy-car, tea, floor getting nearer...;

- at least, I was awake; cleaned up

- forgot to take out adhesive off the box

- middle row, undermost box of 6, all stacked on each other; success!

- glue dried up

- car, parking place, store, car, parking ticket; 1 hour

- repaired machine, had coffee; 2 hours, but relaxing

- back to layout, hit SAVE, success; 1 hour

- turned on milling PC: "no operating system"; WHAT NEXT?

- removed 2 others PC on top, disassembled the crap, refitted S-ATA cable with 2 min epoxy (suffer, suffer!)

- turned on milling machine, *click* nothing

- actually it WAS on, already; at least, I then knew why the circuit breaker triggered the day before...

- not that heavy (70kg), but completely surrounded by other equipment, including the 3 PCs from before...

- spent rest of the day repairing the machine (standard fault, switching PSU, electrolytic capacitors)

- had coffee; nothing happened

- milling PC and machine ON; nothing extraordinary happened

- prepared machine, PCB, program, homing axes...

- ***WHAM*** there went 45 bucks (EUR); a brand new LPKF RF 6mil end mill

- forgot to attach the z axis home switch, that bad day #2, before

- another mill, another try; success, but another two hours gone...

- milled out board manually on another machine

- cleaned that nasty, sticky FR4 above the bathroom sink

- *plop* down the drain...

- took off U-pipe, found PCB, matchbox car and a barrette

- needed coffee... only 1l milk left? -> children built an "invisible" submarine; creative but annoying...

- carefully, virtually trembling, soldered PCB

- success; blackout

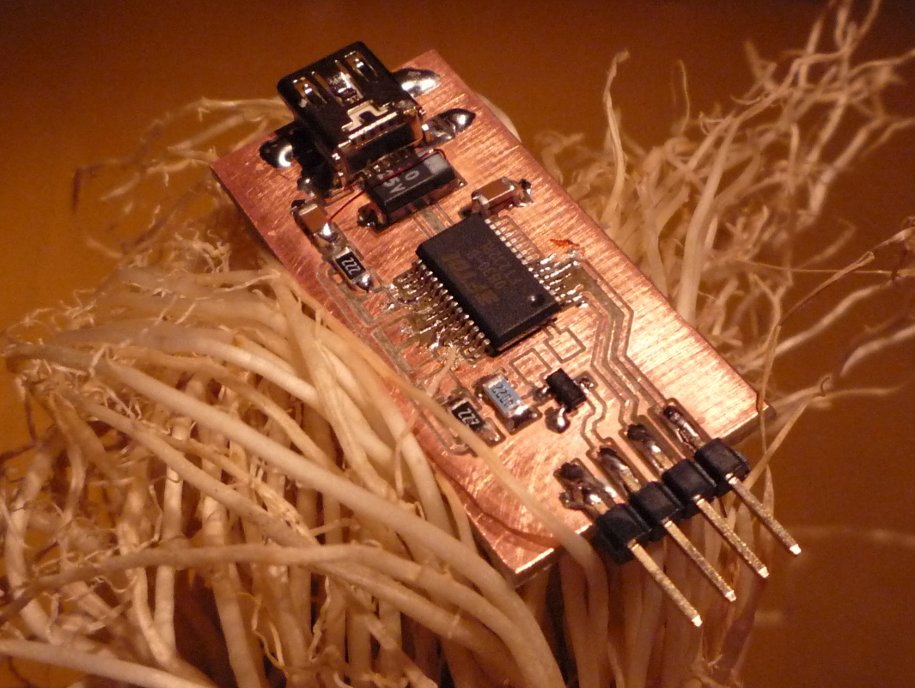

Hardware

The layout was created for milling machines (and without solder resist):

- one power connection was intentionally left out (avoids short circuits under USB plug)

- all attached FTDI pins were made a little longer (easier soldering)

There is nothing more to say about this ... little thing.

Use the library/schematics/layout as a quick starting point for your own stuff...

the damn schematic

|

the f****** layout

|

NOTE 11/2010:

What can you do, if all your milled prototypes were stolen by software guys?

Right. You won't ever see them again (the prototypes =), make a series...

the (almost unchanged) schematic

|

a nicer, smaller layout

|

Useless Pics

SPIF TORX-receiver on-board

|

a closer view

|

and the connections

|

Download

MiniFTDI:

Includes:

- schematic (PDF)

- schematic (SCH)

- placement (PDF)

- layout (BRD)

DOWNLOAD: miniftdi V1 V1.0 (biiig and longer pads (for milling))

DOWNLOAD: miniftdi V2 V2.0 (smaller)

The driver can be downloaded, here.

ASkr 12/2009 initial (and forever lasting ;-) version

ASkr 11/2010 updated docs for smaller V20 version